Optical Fiber

Optical fiber

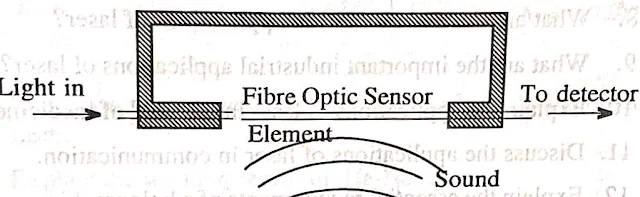

An optical fiber is a flexible glass or plastic fiber that can transmit light from one end to the other. Such fibers are used widely in fiber-optic communications. They permit transmission over longer distances and at higher bandwidths (data transfer rates) than electrical cables. Fibers are used instead of metal wires because signals travel along them with less loss and are immune to electromagnetic interference. [7] They can carry light into or images out of confined spaces, as in the case of a fiberscope. [8] Specially designed fibers have a variety of other applications, such as fiber optic sensors and fiber lasers. [9]

Drawing is a process for making glass optical fibers. For plastic fibers, we can choose either drawing or extrusion. [10][11] Optical fibers typically include a core surrounded by a transparent cladding material with a lower index of refraction. The core keeps the light in the core by total internal reflection, which causes the fiber to act as a waveguide. [12]

Optical fibers joined together, with low loss, have a significant role in fiber optic communication. [17] It is more complex than joining electrical wire or cable and involves careful cleaving of the fibers, precise alignment of the fiber cores, and coupling of these aligned cores.

Principles of optical fiber:

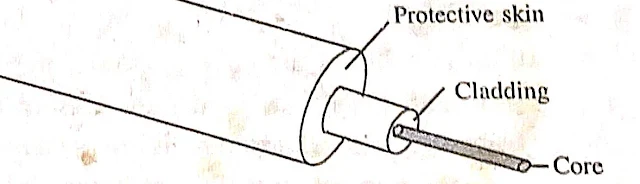

Optical fiber is a thin, cylindrical, transparent dielectric material surrounded by another dielectric material of comparatively low refractive index.

- It consists of a core, cladding, and an outer jacket.

- Light admitted to one end of the inner core undergoes repeated total internal reflection and propagates to the other end.

Total internal reflection at the core-cladding interface occurs only when it meets the following conditions.

1) The refractive index of the core material must be greater than that of the cladding (This allows the light ray to travel from a denser to a rarer medium).

2) At the core-cladding interface, the angle of incidence must be greater than the critical angle.

Since it travels from a denser to a rarer medium, the angle of refraction is greater than the angle of incidence. As the angle of incidence increases, the angle of refraction also increases. For a particular angle of incidence, the refracted ray grazes the core-cladding interface. This angle is called the critical angle. With further increase of angle of incidence, the light ray reflected into the core, obeying the laws of reflection. This phenomenon is called total internal reflection.

- Light rays that make the angle of incidence higher than the critical angle at the core-cladding interface undergo total internal reflection and propagate through the fiber.

- The rotation of the acceptance angle about the fiber axis shown below describes the acceptance cone of the fiber.

- Light launched at the fiber end within this acceptance cone will be accepted and propagated through the core.

Single and multi-mode fibers:

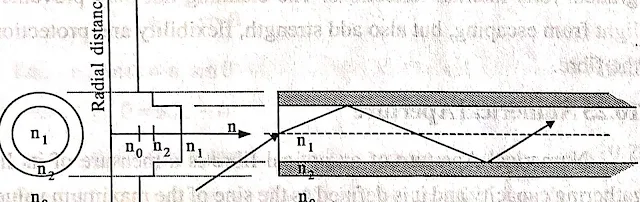

The refractive index of the core of a step-index

fiber (n1) is constant. The refractive index of cladding (n2)

is also constant but less than that of fiber core. The cross-sectional index

profile of the fiber, taking the refractive index along the X direction and

radial distance from the axis along the Y axis, shows a step-like profile.

Hence, the name step-index fiber.

When light enters into the fiber, it undergoes

repeated total internal reflection.

Significant features:

- Refractive

indices of core (n1) and cladding (n2) are constant

- n1>n2

- The

path of the light ray inside the fiber is the saw-tooth pattern.

no, n1, and n2 - Refractive indices of air, core, and cladding respectively.Index profile of a step-index fiber

Graded index fiber:

The refractive index of the core of a graded-index fiber (n1) is not a constant. The refractive index at the center of the fiber core is maximum, and it reduces gradually as the radial distance increases. It reaches a minimum value at the core-cladding interface. The refractive index of cladding (n2) is constant but less than that of fiber core. The cross-sectional index profile of the fiber, taking the refractive index along the X direction and radial distance from the axis along the Y axis, shows a sine wave pattern.

When light enters into the fiber, it undergoes repeated total internal reflection.

Significant features:

- The refractive index of the core is not a constant (n1)

- The refractive index of cladding (n2) is a constant

- n1>n2

- The path of the light ray inside the fiber is a sine wave pattern.

In fiber optic communication, the transmitted signal is the form of

pulses with a given width, amplitude, and spacing between pulses. During

transmission, dispersion causes the widening and overlapping of adjacent

pulses. This increase in pulse separation forces us to increase the pulse

separation to avoid overlapping.

It leads us to reduce the limit of the pulse transmission rate. The

maximum allowable transmission rate is called bandwidth. The product of

dispersion and bandwidth (BDP) is a factor in determining the quality of the

fiber.

The power of the light at the output is always less than that of the input light. The loss is a function of the material, wavelength of light, and the fiber length. These losses have two sources.

- scattering loss

- absorption loss

The inhomogeneities that occurred during the fabrication of fiber led to scattering loss.

The glass in optical fiber is an amorphous solid formed by allowing the glass to cool from its molten state at a high temperature until it freezes. Fabrication of fiber is drawing this glass under proper tension. During this process, submicroscopic variations in the density of the glass in the fiber cause scattering. Dopants added to silica to modify the refractive index also cause fluctuation in the refractive index.

Absorption of infrared photons by atoms within the glass molecule increases the random mechanical vibration and heating. Trapping minute quantities of water molecules and other impurities like iron, copper, chromium, etc. creates unacceptable losses. Hence, extra care is essential during the purification of silica.

Now we know the importance of proper material and technology to manufacture good quality fiber. Using glass and plastics, we can fabricate the fiber. Plastic fibers are easy to manufacture at a low cost, and losses are high. It is suitable for short-distance communication. Plastic-coated silica fibers are easy to manufacture. Solid silica cladding makes this fiber useful in medium-distance moderate bandwidth communication systems.

For glass fibers, the material used is silica (SiO2). It is possible to vary the refractive index by adding dopants.

Advantages of optical fiber:

- Large information-carrying capacity

- Cost-effective

- Low transmission loss

- Small size, so suitable for spaceship and aircraft applications

- Immune to electromagnetic interference

- It eliminates cross-talk and secrecy provided to use in defense.

- Made of silica and glass, which is abundant in nature and very cheap.

- An important role in computer links, space vehicles, industrial automation, etc.

For applications that demand a permanent connection, a fusion splice is popular. In this technique, an electric arc can melt the ends of the fibers together. Another common technique is a mechanical splice, where the ends of the fibers are in contact by mechanical force. Temporary or semi-permanent connections are possible using specialized optical fiber connectors. [18]

ST connectors on multi-mode fiber [6]

In applied science and engineering, the design and application of optical fibers, known as fiber optics, was coined by Indian-American physicist Narinder Singh Kapany. [19]

- Unit 1 is the subscriber's telephone, where the conversion of sound waves into a corresponding electrical signal.

- Unit 2 is an encoder. It converts continuous electrical signals into coded digital pulses.

- Unit 3 is the transmitter. It usually consists of a miniature semiconductor laser or LED. Modulation of light and signal happens here.

- This encoded optical signal is transmitted to the optical fiber Unit 4.

- Unit 5 is a semiconductor photodetector that converts optical signals into electrical pulses.

- Unit 6 is a decoder. There, conversion from the digital pulse into an analog signal.

- Unit 7 is a subscriber's telephone, where the reproduction of sound from the electrical signal.

9^ Lee, Byoungho (2003). "Review of the present status of optical fiber sensors". Optical Fiber Technology. 9 (2): 57–79. Bibcode:2003OptFT...9...57L. doi:10.1016/s1068-5200(02)00527-8

11 ^ "Manufacture of Perfluorinated Plastic Optical Fibers" (PDF). chromisfiber.com. 2004. Retrieved 2023-09-11.

13^ Pearsall, Thomas (2010). Photonics Essentials (2nd ed.). McGraw-Hill. ISBN 978-0-07-162935-5. Archived from the original on 2021-08-17. Retrieved 2021-02-24.

16^ Fennelly, Lawrence J. (26 November 2012). Effective Physical Security (4th ed.). Elsevier Science. p. 355. ISBN 9780124159815.

19^ "Narinder Singh Kapany Chair in Opto-electronics". ucsc.edu. Archived from the original on 2017-05-21. Retrieved 2016-11-01.

Comments

Post a Comment