Solid State Laser: Ruby

Solid-state lasers are attractive sources of coherent radiation for various applications.

The five groups of lasers are solid-state, semiconductor, liquid, gas, and plasma.

The state of the laser active environment in solid and semiconductor lasers is similar, so they are in a single group.

Research in solid-state lasers has been continued for more than 50 years and gradually progressed in obtaining new emission wavelengths and tunable radiations. A new generation of solid-state laser systems pumped, fiber, slab, and disc lasers has begun a new era in the research and development of medical instruments due to the reduction of the size and consumption of energy (1-2).

Lasing medium is host material doped by a laser-active material. Host material does not directly participate in the lasing action. The host materials are usually glass or dielectric crystals. Some combinations for forming a lasing medium are:

- Aluminum oxide (Al2O3) doped with triply ionized chromium (Cr3+) for Ruby laser.

The substitution of chromium ions to Aluminium ions converts it into ruby (Cr2O3), the active material in ruby laser.

- Yttrium Aluminium Garnet (y3Al5O12) is known as YAG, doped with neodymium (Nd3+) for Nd: YAG laser.

- Doping neodymium with glass will form the active medium for Nd: glass laser.

Solid-state lasers made use of optical pumping for population inversion. A light source supplies energy for excitation. Elliptical reflectors help to focus maximum light on the lasing medium.

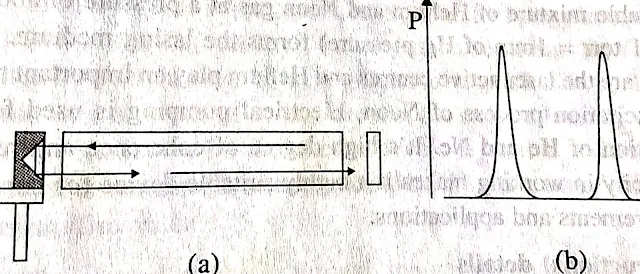

The parallel and silvered end faces (one face partially silvered and the other fully silvered or polished) of the medium (or mirrors) form the cavity resonator.

In this article, I discuss the working of ruby laser.

The American Physicist Theodore Maimann developed this laser in 1960. Ruby is a transparent pink-colored material made of Aluminium oxide and triply ionized chromium

(0.05% to 0.5% chromium). The pink color is due to the presence of chromium.

Ruby crystal, cut into a cylindrical shape with 10 cm length and 1 cm diameter. One silvered face is for fully reflecting, and the other is for partially reflecting. These ends act as reflecting mirrors of the optical resonator. A helical-shaped Xenon flash lamp around the ruby is for optical pumping. Suitable reflectors focus the light on the ruby rod.

The energy level diagram of ruby shows wave numbers (1/λ) along the vertical axis. We can calculate energy directly by multiplying wave number by hc. Energy E=hc/ λ.

The ground level E1 acts as a lower lasing level. E2 is the metastable level, and E3 and E4 are excited levels.

The first step is to activate the xenon flash lamp. The lamp releases a few kilojoules of energy. The chromium ions selectively absorb blue (0.4µm) and green-yellow (0.55 µm) radiation and undergo an excitation transition to E4 and E3 levels.

The efficiency of the ruby laser is 1% or less. Only a few tens of joules of energy appear at the output. The rest appears as heat in the lasing medium. We can resolve this by providing a suitable cooling arrangement. The output power is equivalent to 10 to 20 kW.

Features:

- Output is in pulse mode and spiky

- Efficiency 1% or less

- Output power 10 to 20 kW

- A cooling system is needed to avoid extra heating.

The output energy of the ruby laser is coherent but spread over short pulses. We can concentrate this energy into a short-duration giant pulse using Q-switching arrangements. For Q-switching, we need to replace the fully reflecting mirror of the resonator with a reflecting prism. This prism spins rapidly around the axis and is at right angles to the axis of the resonator. During each rotation, the reflecting face of the prism faces the radiation for a short time. Lasing action takes place when the mirrors are parallel. If the rotation speed of the prism is 100 revolutions per second, then the cavity switches from minimum to maximum in about 0.1µs. Then, we get the laser output in a giant pulse with a width of less than 0.1 µs. The peak power increases and is of the order of 50MW.

Applications

By 1964, ruby lasers with rotating prism q-switches became the standard for military rangefinders. One decade later, the introduction of more efficient Nd: YAG rangefinders replaced q-switches. Ruby lasers were used mainly in research. [6] The ruby laser was the first laser to pump tunable dye lasers optically. Particularly well suited to excite laser dyes emitting in the near-infrared region. [7] The use of ruby laser is rare in industry, mainly due to low efficiency and low repetition rates. One of the industrial uses is drilling holes through the diamond because the ruby's high-powered beam closely matches the diamond's broad absorption band (the GR1 band) in the red.[6][8]

Ruby lasers have declined in use with the discovery of better lasing media. They have several applications where short pulses of red light are required.

Holographers worldwide produce holographic portraits with ruby lasers in sizes up to a meter square. Because of its high pulsed power and good coherence length, the red 694 nm laser light prefers the 532 nm green light of frequency-doubled Nd: YAG, which often requires multiple pulses for large holograms. [9] Many non-destructive testing labs use ruby lasers to create holograms of large objects, such as aircraft tires, to look for weaknesses in the lining.

To learn more about holography, please read my article (https://retnacpn.blogspot.com/2023/10/science-of-holography.html).

Ruby lasers are applied extensively in tattoo and hair removal. But are replaced by alexandrite and Nd: YAG lasers in this application. [5]

1

Sciencedirect.com

7^ F. J. Duarte, and L. W. Hillman (Eds.) (1990). Dye Laser Principles. Academic. pp. 240–246.

8^ Walker, J (1979-10-01). "Optical absorption and luminescence in diamond". Reports on Progress in Physics. 42 (10): 1605–1659. CiteSeerX 10.1.1.467.443. doi:10.1088/0034-4885/42/10/001. ISSN 0034-4885. S2CID 250857323

9^ Silfvast, William Thomas. Laser Fundamentals. Cambridge University. p. 550.

Comments

Post a Comment